Controlled atmosphere areas

Mecotec is an independent company expert in the verification and compliance of industrial measuring instruments and in the qualification and validation of equipment and clean rooms. In this context, our company is responsible for verifying viable particles (fungi, bacteria, viruses and spores) and non-viable (dust) in controlled Atmosphere Zones (also called Clean Rooms qualification, white rooms or even clean rooms).

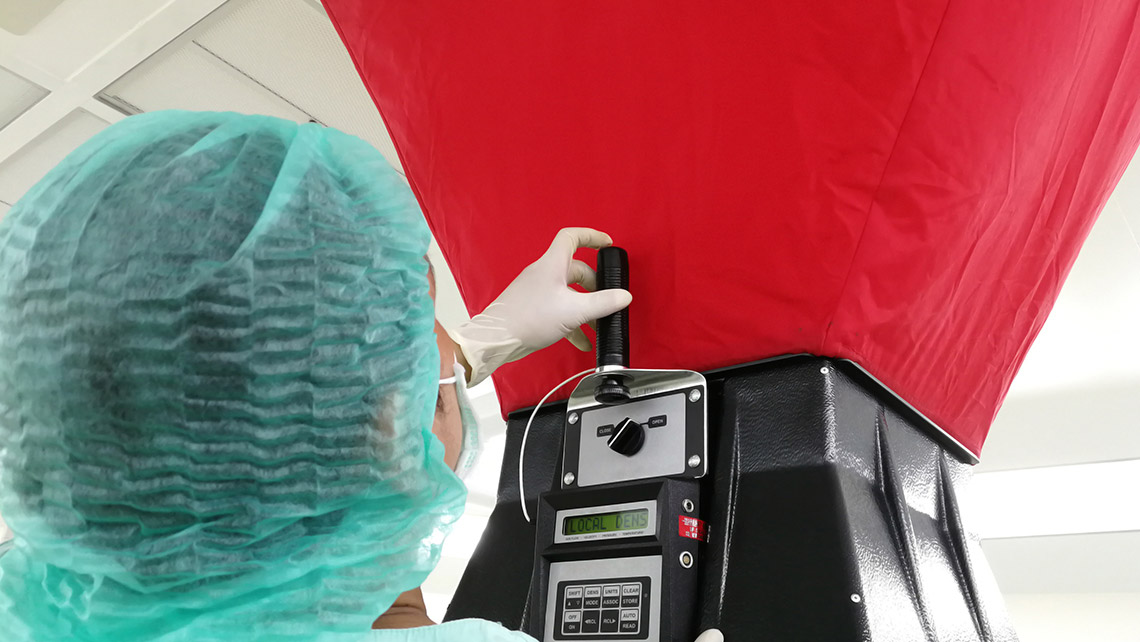

Our Clean Rooms qualification services in images

Below, discover our Clean Rooms qualification services through a photo gallery:

Controlled Atmosphere Zones and controlled Atmosphere Chambers

Our experts ensure the verification of the microbiological environmental quality- that is to say the concentration of viable particles (fungi, bacteria, viruses, and spores) – as well as the particle classification (at rest, in other words when no one is present in the area, or in activity, when personnel are busy working in the area) – i.e. the concentration of non-viable particles (mainly dust) - of controlled Atmosphere area and Atmosphere Chambers controlled (smaller areas within Clean Rooms qualification). This ensures GMP (Good Manufacturing Practices) compliance of these spaces.

Our services concern all clean rooms where semiconductor, biotechnological, microelectronic devices, vaccines are manufactured, but also operating rooms, operating theatres (for humans or animals), etc. These areas require careful testing of the particle concentration to minimize the risk of particle introduction, generation and retention within them.

Our team goes on site and performs, using state-of-the-art equipment, the qualifications laminar flow hoods, microbiological safety workbench the safety (user protection) or biosafety (user and product protection), or insulators

In terms of particle classification (non-viable particles), we have set up a series of test for you:

- Measurement of the total supply volume flow rate and of the air renewal rate

- Verification of differential static pressure;

- Checking the tightness of the assembly and the integrity of the absolute supply and extraction filters

- Verification of the pressure drop of the filters;

- Verification of the Cleanrooms Classification;

- Verification of the recovery time;

- Verification of the air flow pattern by a smoke study ;

- Room temperature and humidity .

In terms of microbiological environmental qualification (viable particles), we check the aero biocontamination of aseptic production areas and isolators using 3 distinct methods:

- Aero biocontamination by impaction: use of an air sampler to perform the measurements

- Aero biocontamination by contact: placement of agar plates on certain areas of frequent contact

- Aero biocontamination by sedimentation: deposit of agar culture media on a flat surface for a determined time.

Heating Systems, Ventilation and Air-Conditioning (HVAC)

Heating, Ventilation and Air-Conditioning (HVAC) systems are cleanrooms filtration/ ventilation systems. As part of our activities, we ensure the verification of the correct functioning of the HVACs and the classification of the area so that it meets the established standards.

Personal Air Lock (PAL) and Material Air Lock (MAL)

Personal Air Lock (PAL) and Material Air Locks (MAL) are airlocks serving as intermediate areas useful in ling the transfer of contaminated air from one area to another. It is important to check that these zones are functioning correctly and that they meet the current standards.

Verification of the production units Compressed Air Process

The production units Compressed Air Process must be flawless. Our teams verify the purity class and the content of non-viable solid particles of compressed air, for networks up to 10 bars, used by production units in clean rooms. This involves precisely determining the particulate concentrations present in the air/ gas and categorizing them by size.

Contact us for more information!

Would you like to know more about our services relating to the control and compliance of clean rooms? Please contact our team of specialists at your service via the online form and by phone.

Partager ce contenu

Partager ce contenu